Introduction by Kelvin Kwok

Freshwater is an important resource in many countries especially developing ones, and many people in these regions do not really have access to it in daily life.

Unfortunately, this issue tends to receive much less attention compared to, say, air pollution, partly because it seems less relevant to the buzzwords like global warming, but also because it does not really affect the most developed countries that are currently steering the climate change campaigns.

Here Kelvin Kwok shares an article about China’s grand project of relocating a colossal body of freshwater, designed to mitigate disastrous floods in the south on one hand, and to rehydrate the dry north on the other – hitting two birds with one stone.

This project – coined South-North Water Transfer Project (南水北调) – was first suggested by Chairman Mao more almost 70 years ago. But it took another 50 years of planning before the project was finally initiated, and more than a decade to show progress. This shows how challenging the project was.

The first phase was finally completed in 2014 when almost all water resources in Beijing and the entire North China Plain were dried out. The results are very apparent though, now that freshwater supply is no longer an immediate crisis. But apart from transferring water itself, many other factors have to be accounted for in the project, including environmental disruption, relocation of local residents, water quality, etc.

It takes immense determination to overcome all these obstacles, which is still an ongoing battle..This article describes pretty much everything you will need to know about this astonishing multi-decade engineering project. Perhaps it could be a valuable reference for other countries struggling with similar issues.

Contributed by Kelvin Kwok, 16 October 2021, to China Environment on FB https://www.facebook.com/groups/2516109708443374/posts/4468510743203251/

SOURCE: K in the Clouds blog, 28 July 2020. https://kblog.health.blog/…/28/south-north-water-transfer/

Original piece:《南水北调,难!》

Produced by Institute for Planets (星球研究所)

Written by 桢公子

Translated by Kelvin Kwok

The Full Article

This is the longest piece ever produced by the Institute for Planets.

It took 20 days in total for the team just to comprehend the fundamentals of this enormous engineering project.

We hope to satisfy our readers’ curiosity about it, and to share its history and development to as many as possible.

Like all metro stations in China, the Wukesong Station in Beijing is busy as ever. Passengers come and go while trains shuttle through as the years pass and the days go by.

But there is no other metro platform like the one in Wukesong Station. Just 3.67 metres below its surface, two massive concrete culverts run in parallel through the platform, carrying restless river water from afar that surges thousands of miles to the north.

From here, the river water will traverse 2 railways, 4 rivers, 8 footbridges and 23 interchange bridges, then crisscross with more than a 100 underground pipelines, before it finally merges with rivers and lakes, resides in reservoirs and eventually reaches thousands of households.

(diagram: 陈睿婷, Institute for Planets)

Perhaps the busy crowd on the platform will never notice the coursing current underneath their feet. Nor will the 120 million citizens from more than 260 counties and 40 large and medium cities across the North China Plain ever feel its presence.

Nonetheless, an unforeseen transformation is happening quietly every minute. Before these citizens realise, their way of living and the fate of their hometowns will never be the same again.

Thanks to an unprecedented mega engineering project – the South-North Water Transfer Project.

(photo: 韩自豪, please view with landscape mode)

1. The dry lands of Northern China 干渴的华北

According to calculations on freshwater resources per capita, the driest area in China is not the northwest region largely covered by deserts, but the North China Plain.

In particular, the Jing-Jin-Ji Metropolitan Region, which is home to 8% of China’s population and contributes 10% of the country’s GDP, has water resources per capita far below the internationally standardised limit for absolute water scarcity of 500 cubic metres per year per capita.

The diagram shows water resources per capita in China (中国人均水资源量) measured in cubic metre/person (m3/人), comparing among global (世界), China (中国), and Hebei (河北), Beijing (北京), Tianjin (天津), or collectively known as the Jing-Jin-Ji Metropolitan Region

The limit for absolute water scarcity (极度缺水线) is indicated by the dotted line

Data source: National Bureau of Statistics of China (国家统计局) & World Bank (世界银行)

(diagram: 王朝阳 & 陈睿婷, Institute for Planets)

Moreover, the ever-growing population, continuous urbanisation and rapid industrialisation have severely polluted the Yellow River, Huai River and the Hai River that flow through the North China Plain. These regions were notorious for having the worst surface water quality in China, where ‘all rivers are either dried or polluted (有河皆枯、有水皆污)’.

Water quality in China is categorised into 6 grades: I, II, III, IV, V and Below V

The seven major river systems include Hai River (海河), Liao River (辽河), Huai River (淮河), Yellow River (黄河), Songhua River (松花江), Yangtze River (长江) and Pearl River (珠江)

Data source: China Environmental Status Bulletin 2003 (2003中国环境状况公报)

(diagram: 王朝阳 & 陈睿婷, Institute for Planets)

Little surface water was left due to water shortage and pollution.

As a result, people had no choice but to turn to other means, including over-exploitation of groundwater and the reuse of reclaimed water. Some even laid hands on precious water resources intended for sustainability purposes for the ecosystem.

(photo: VCG)

By early 21st century, exploitation of groundwater in the Jing-Jin-Ji Region had already exceeded 100%. An underground overdraft area larger than 90,000 square kilometres soon appeared in the North China Plain and kept growing.

The degree of groundwater exploitation can be expressed as the exploitation coefficient, which is the ratio of the actual exploitation to the exploitable amount of groundwater; groundwater overdraft is defined by a coefficient of >100%.

Cities: Xinxiang (新乡), Hebi (鹤壁), Anyang (安阳), Handan (邯郸), Xingtai (邢台), Shijiazhuang (石家庄), Baoding (保定), Beijing (北京), Tangshan (唐山)

Data source: 100 Q&As on South-North Water Transfer Project (南水北调工程知识百问百答)

(diagram: 王朝阳 & 陈睿婷, Institute for Planets)

The Miyun Reservoir, a major source of water supply for Beijing, shrunk by 75% in volume within merely 4 years between 1999 and 2003. More than 70% of the city’s water demand therefore could only be met by extracting groundwater. This caused the groundwater level of the Beijing plains to drop at a rate of 1 metre per year.

(photo: VCG)

The city of Jinan also suffered from serious groundwater overdraft. With fountain attractions disappearing in large numbers, the “fountain city” was in a deeply precarious situation. In some regions of Hebei Province, where over-exploitation was even worse, groundwater was expected to get completely exhausted within 20 years.

(photo: VCG)

Since 2003, a range of water-saving measures were taken in Beijing over the next ten years. Water consumption per 10,000-yuan GDP was reduced by almost 70%, and 22% of the water supply was replaced by reclaimed water.

Unfortunately, these measures were not sufficient to counter the scarcity of surface water and the constantly increasing water consumption of a growing population.

Groundwater level continued to drop.

Every region in China, south and north, deserves equal opportunity to develop and prosper.

But the extreme water shortage in Northern China severely impeded development in the region. A new water source is urgently needed to rescue the dire situation. If only there is one.

But there is always hope, no matter how slim.

Thousands of miles away, the vast Yangtze River rages across the midlands of China with a multi-year average runoff volume of approximately 960 billion cubic metres. This is almost 7 times the total runoff volume of Yellow River, Huai River and Hai River combined.

People could not help but wonder: could the water of Yangtze River be channeled north?

Simple as it sounds, constructing a water transfer infrastructure that spans thousands of miles is no ordinary challenge.

2. The impossible mission 艰难的工程

The concept of south-north water transfer was actually proposed in as early as 1952.

But it was not until 2002 before the project master plan was ready.

From the grand layout of transfer routes and scaling of the project, to the structure of aqueducts and construction materials for water pipes, it took half a century of repetitive validation to finalise all the meticulous details.

According to the multi-decade master plan, there will ultimately be three massive water channels, the Eastern, Central and Western Routes, running from south to north across China. Together with the east-flowing Hai River, Yellow River, Huai River and Yangtze River, they will form a gigantic ‘four horizontal and three vertical‘ water network.

The three routes are designed to send 44.8 billion cubic metres of water annually to the north. This volume is approximately 4.7% of the multi-year average runoff of Yangtze River, but almost 80% of that of Yellow River.

The completed Phase I of the Eastern and Central Routes have a water transfer volume of 8.8 and 9.5 billion cubic metres respectively, whereas the feasibility of the Western Route is still being explored

These figures are based on multi-year average values, and the actual volume of water transfer is adjusted according to the yearly water demand

(diagram: 王朝阳 & 陈睿婷, Institute for Planets)

The South-North Water Transfer Project was not the first of its kind.

By the time it was initiated, there were already about 400 water diversion projects completed globally. But the scale of water transfer, the area of land covered and the population size involved in this project were truly unrivalled.

It was therefore a historical moment for the hydraulic engineering field when the Phase I of Eastern and Central Routes started operating on the 15 November 2013 and 12 December 2014 respectively.

(photo: VCG)

But who would have imagined what it took to accomplish this impossible mission?

2.1 Eastern Route: defying gravity 东线:水往高处流?

The entire Eastern Route spans 1785 kilometres.

It voyages north from Yangzhou, Jiangsu, leaps across the Huai River and tunnels through the Yellow River. Finally, it delivers the water of Yangtze River to Tianjin and the Shandong Peninsula.

The completed Eastern Route Phase I is 1467 kilometres long

. The aqueduct on top serves as both the water transfer channel of the Eastern Route Phase I, and the waterway of the Beijing-Hangzhou Grand Canal; the culvert beneath is the sea-entering channel of Huai River

This is the largest water interchange system in Asia

(photo: 贺敬华)

Accompanying this journey are several north-flowing rivers including the Beijing-Hangzhou Grand Canal, all of which act as ready-made channels for the travelling water from the Yangtze River.

Photo taken in Zaohe Town, Suyu District, Suqian, Jiangsu

(photo: 李琼)

Several lakes scattered along the way, including the Hongze Lake, Luoma Lake, Nansi Lake and Dongping Lake, are natural reservoirs for water transfer management.

(photo: 李琼)

In addition, with the established groundwork of a preexisting river water diversion project in Jiangsu, it seemed all conditions for the construction of Eastern Route were ripe. The arrival of success was just a matter of time.

The first and second pumping stations were previously built for the completed river water diversion project

(photo: 缪宜江)

But things are never as easy as they seem.

From the starting point of the water transfer to the southern bank of Yellow River in midway, there is an elevation of almost 40 metres. This means that the northbound water from the south will have to defy gravity and flow upwards.

Only when it treks through the highest elevation point, can it freely stream down to Tianjin, or gallop towards Shandong Peninsula via the Yellow River-to-Qingdao Water Diversion Project.

Elevation (高程, left): ground surface line (地面线, yellow) and water surface line (水面线, blue)

Cities: Beijing (北京), Tianjin (天津), Cangzhou (沧州), Hengshui (衡水), Dezhou (德州), Liaocheng (聊城), Jinan (济南), Zibo (淄博), Weifang (潍坊), Yantai (烟台), Weihai (威海), Qingdao (青岛), Jining (济宁), Zaozhuang (枣庄), Xuzhou (徐州), Suqian (宿迁), Huaian (淮安), Yangzhou (扬州), Nanjing (南京), Hefei (合肥), Wuhan (武汉)

Checkpoints (yellow dot): Tianjin, Yellow River Tunnel Project (穿黄工程), Nansi Lake Second Stage Dam (南四湖二级坝), Huaian Hydraulic Hub (淮安水利枢纽), Jiangdu Hydraulic Hub (江都水利枢纽)

Red dots indicate water pump stations (抽水泵站)

(diagram: 王朝阳 & 陈睿婷, Institute for Planets)

So, 34 control sites with 160 water pumps were built just for Eastern Route Phase I.

This 13-stage pumping station cluster, the largest of its kind in the world, sends water from the Yangtze River 40 metres uphill in a step-wise manner, from the Jiangdu Hydraulic Hub in Yangzhou all the way to the southern bank of Yellow River.

To minimize the energy consumption of the pumping station cluster, an innovative design is used in a third of all the pumps.

It took Chinese engineers 3 years to develop this so-called bulb tubular pump, which allows water to flow straight through without having to turn around in curling pipes.

Basic components: guide vane (导叶), impeller (叶轮) and bulb body (灯泡头)

(diagram: 郑伯容, Institute for Planets)

Compared to vertical axial flow pumps, bulb tubular pumps greatly improve the energy conversion rate from 65% to 81%, making them much more efficient.

(diagram: 郑伯容, Institute for Planets)

With these pumping stations, the water transfer capacity of Eastern Route Phase I reaches up to 8.8 billion cubic metres. This is equivalent to supplying 600 times the volume of the West Lake to each of Jiangsu, Anhui and Shandong Provinces.

(photo: 潘锐之)

On the contrary, the Central Route seems to be far more energy-efficient.

There is only one pumping station throughout the whole route that stretches 1432 kilometres.

What makes this possible?

2.2 Central Route: one-way stream to the north 中线:一渠清水向北流

September, 2005.

A loud blast rang through the mountains somewhere 800 metres downstream of the confluence of Han River and Dan River in Hubei. This marked the beginning of the demolition work on the surface of the Danjiangkou Dam.

Soon later, the dam underwent a 14.6-metre heightening with a new concrete layer. This increased the area of Danjiangkou Reservoir by 1022 square kilometres, making it almost on par with that of the Three Gorges Reservoir.

The Danjiangkou Reservoir sits at the junction between Xichuan County in Henan and Danjiangkou City in Hubei

(photo: Promotion Centre of the Construction and Administration Bureau of South-to-North Water Diversion Middle Route Project 南水北调中线干线工程建设管理局宣传中心)

However, it was extremely challenging to remould a dam that had been in service for almost 40 years.

Any unexpected thermal contraction and expansion due to temperature difference between the old and new concrete would form cracks in the dam structure.

This would be catastrophic.

To avoid this, the pouring temperature of concrete had to be strictly controlled. In addition, engineers broached arrays of keyways on the old concrete in the weir body of the dam, into which steel bars were implanted. These keyways greatly strengthened the fitting and anchoring between the old and new concrete layers.

Diagram illustrates the heightening of the overflow dam section, where steel bars (also known as anchor bars) are implanted into the keyways

(diagram: 郑伯容, Institute for Planets)

On the top part of the dam, a total of 1164 steel bars were implanted into the 20 gate piers to consolidate the pier structure.

(diagram: 郑伯容, Institute for Planets)

The heightening project lasted almost 8 years.

With a taller and thicker dam structure, the Danjiangkou Reservoir not only has sufficient volume to fulfil the needs of the water transfer project, but also a water level up to 170 metres, which is more than 100 metres above the elevation of Beijing.

This means that the gurgling water in the Danjiangkou Reservoir can just smoothly flow into Beijing without any help from pumping stations.

The 1432 kilometres long Central Route includes a main trunk line (1276 kilometres) reaching Beijing, and a Tianjin trunk line (156 kilometres)

Elevation (right): ground surface line (yellow) and water surface line (blue)

Cities: Beijing (北京), Tianjin (天津), Baoding (保定), Shijiazhuang (石家庄), Xingyai (邢台). Handan (邯郸), Anyang (安阳), Hebi (鹤壁), Xinxiang (新乡), Jiaozuo (焦作), Zhengzhou (郑州), Xuchang (许昌), Pingdingshan (平顶山), Nanyang (南阳)

Checkpoints (yellow dot): Tuancheng Lake (团城湖), Tianjin Trunk Line Water Diversion Port (天津干渠分水口), Gubaizui Tunnel (孤柏嘴穿黄工程), Sha River (沙河), Fangcheng Saddle (方城垭口), Tuan River (湍河), Taocha Diversion Hub (陶岔渠首枢纽)

(diagram: 王朝阳 & 陈睿婷, Institute for Planets)

Or be diverted east into Tianjin via the Xiheishan Diversion Port in Baoding, Hebei.

(photo: Promotion Centre of the Construction and Administration Bureau of South-to-North Water Diversion Middle Route Project)

Construction of this route is blessed by the existence of a mountain pass near Fangcheng County in Nanyang, Henan, along the watershed that splits up the Yangtze River and Huai River basins.

This ‘gap’ in the rolling mountains is known as the Fangcheng Saddle.

While the elevation of neighbouring mountains is above 200 metres, it is only 145 metres at the Fangcheng Saddle. This allows the water channel of the Central Route to trail downwards through the mountains, saving the effort of thousands of miles of tunnel drilling.

The saddle lies between the Tongbai Mountain (桐柏山) and Funiu Mountain (伏牛山); the channel across the saddle is 7.6 kilometres in length

(diagram: 王朝阳 & 陈睿婷, Institute for Planets)

However, one cannot have it both ways.

Although no pumping stations were needed for the Central Route, there was no existing water channels that can be readily utilised. The entire Central Route, which is 1432 kilometres in length, had to be built from scratch.

This was destined to be a long and challenging process.

The old gate built in 1973 can no longer fulfil the needs of the South-North Water Transfer Project; photo shows the reconstructed gate dam

(photo: Promotion Centre of the Construction and Administration Bureau of South-to-North Water Diversion Middle Route Project)

Along its way, the Central Route has to cross a total of 686 rivers of all sizes.

To ensure the water quality is protected from floods and pollution, large water interchanges are erected one after another. Among these are 27 large beam aqueducts, on which the water from the south endlessly course through like a “river of the heavens” that meanders north.

(photo: Promotion Centre of the Construction and Administration Bureau of South-to-North Water Diversion Middle Route Project)

In Henan, the Sha River Aqueduct has a total length of 11.9 kilometres.

The enormous U-shaped groove sections of the aqueduct each weigh 1200 tons. Hoisting one section is equivalent to hoisting 1000 cars at a time.

Photo was taken on 10 May 2012 during the construction of the Sha River Aqueduct

(photo: 何进文)

To the south of Sha River Aqueduct is the Tuan River Aqueduct, which outsizes the former by far. It has an inner diameter of 9 metres, and a single-section span of 40 metres. Each section can weigh up to 1600 tons.

Faced with such enormity, engineers simply gave up on ordinary hoisting equipment.

Instead, they poured concrete directly into large groove building machines on the spot. One section at a time, these engineers successfully built the largest U-shaped aqueduct in the world.

This is the first time it is used in China

(photo: VCG)

But more often, the Central Route dives underground and tunnels through roads and rivers from below using the inverted siphon design. And the most challenging and grandest of all is the Yellow River Tunnel Project that aims to traverse right through the Yellow River.

An inverted siphon design utilises the difference in water levels between upstream and downstream, where water flows down a shaft from former end to the latter, forming a water channel interchange

Water tunnels through the Yellow River (黄河) down an elevation drop (南北落差) of 6 metres

Structures: Mangshan Tunnel (邙山隧道), Yellow River Tunnel (穿黄隧道), shaft (竖井), southern (南岸进水口) and northern bank inlet (北岸进水口)

(diagram: 陈睿婷 Chen Ruiting, Institute for Planets)

The massive cylindrical shaft at the northern bank of Yellow River has an inner diameter of 16.4 metres and a depth of 50.5 metres, in which a 15-storey building can probably fit in without any problem.

From here, a gigantic tunnel boring machine would drill through 4000 metres of thick sand to excavate a tunnel under the Yellow River.

Photo taken on 8 July 2007

(photo: VCG)

Day and night, the cutter head of the tunnel boring machine kept grinding, chipping away crushed rocks and expelling mud. As the excavation progressed at an average depth of 30 metres under the bed of the Yellow River, a pair of 7 metres wide tunnels slowly appeared.

Photo shows one of the tunnels that was undergoing a second lining with prestressed reinforced concrete

This was the first application of composite lining system for tunnels in the world

(photo: VCG)

Excavating a tunnel at such scale was certainly not without obstacles.

Due to the high abundance of quartz in the earth, the cutter head of the tunnel boring machine was severely and repeatedly damaged. Engineers had no choice but to go in and out almost 400 times to manually repair and strengthen the cutters clogged up with mud.

After 500 days of non-stop underground journey, the gigantic tunnel boring machine finally saw the sun from the other side of the river.

(photo: 王颂)

With this, water from the south has finally overcome the last natural moat standing in the way of its journey to the north.

The Central Route can also supply water to the Yellow River during dry seasons

(photo: Promotion Centre of the Construction and Administration Bureau of South-to-North Water Diversion Middle Route Project)

Yet the construction of the Central Route was more than just soaring high or diving deep.

Despite being on a flat plain, about a third of the entire Central Route had to deal with the problematic expansive soil on which it was built. Expansion soil exhibits substantial swelling and shrinking with changing water availability, which can lead to collapse of aqueducts.

Unfortunately, there was not even one precedent for similar projects across the country at the time. This means everything, including even construction standards, had to be established from the ground up.

(photo: VCG)

What also made the engineers go back to the drawing board was the construction of the prestressed concrete cylinder pipes (PCCPs), which are designed to prevent pollution and minimise land use in Beijing.

(photo: VCG)

PCCP has a composite structure that makes it strong and durable, as well as resistant to seepage and earthquakes.

Layers: inner concrete core (混凝土管芯), steel liner (钢筒), outer concrete core (混凝土管芯), prestressed steel wire (预应力钢丝), mortar coating (砂浆保护层), anti-corrosive coal tar epoxy coating (环氧煤沥青外防腐层)

(diagram: 郑伯容, Institute for Planets)

But the PCCPs needed for the Central Route were 4 metres wide and weighed 78 tons per section, much larger than any pipes known to the engineers. They had to perform numerous experiments before finalising on the construction standards.

(photo: VCG)

Beyond that, the Central Route just needs to extend another 13 kilometres with the Buried Culvert Project in the 4th Ring Road of Beijing to reach the finishing line of the project, Tuancheng Lake.

(photo: Promotion Centre of the Construction and Administration Bureau of South-to-North Water Diversion Middle Route Project)

From there, water from the south marches into water treatment plants in cities, or goes through the Jingmi Diversion Channel and restitutes the Miyun Reservoir which was once on the verge of exhaustion.

(photo: 宋佳音)

This marks the completion of the entire Central Route.

The one-way stream to the north will now stop at nothing.

It will punch through mountains.

(photo: Promotion Centre of the Construction and Administration Bureau of South-to-North Water Diversion Middle Route Project)

Cut through cities.

(photo: Promotion Centre of the Construction and Administration Bureau of South-to-North Water Diversion Middle Route Project)

Crisscross with 31 water channels, 51 railways and 1238 highways.

(photo: Promotion Centre of the Construction and Administration Bureau of South-to-North Water Diversion Middle Route Project)

And join all the dots along the thousand-mile route, including 27 aqueducts, 102 inverted siphons, 17 buried culverts, 12 tunnels, 1 pumping station, 476 drainage units and 303 control sites.

(photo: VCG)

However, the challenges of building massive pumping stations and water channels were just the tip of an iceberg in this demanding mega project.

From water quality control, pollution problem, migration of the local population, protection of excavated ancient artefacts to ecological disruption, there were all kinds of pressing issues which, if not taken care of, would severely hinder the progress of the project.

3. The unsung achievements 幕后的故事

The South-North Water Transfer Project officially commenced in 2002.

But the cities along the Eastern Route were obviously more worried than ever.

This was never a surprise, because out of the 36 cross-sectional surface water samples taken from various regions to the south of Yellow River, only one reached Grade III water quality. Some samples even contained pollutants that exceeded the standard limits by more than a hundred times.

These could not be a used as a source for drinking water.

Photo was taken when the Pollutant Diversion Project had just been initiated

(photo: 缪宜江)

To meet the requirements of a safe water supply, the Eastern Route Project had to ensure a Grade III or above water quality for the entire route within 10 years.

A comprehensive pollution control program was put in place immediately.

As a result, more than 700 paper mills in Shandong and 800 chemical corporations in Jiangsu were closed down in the next 10 years for failing to meet emission requirements.

(photo: VCG)

Approximately 4000 cement ships and 24000 outboard motor boats in these two provinces were either replaced or dismantled.

(photo: 李琼)

Along the river coast, 17 ship garbage collection stations and 43 sewage/oil treatment stations were built just for the Jiangsu section of the project.

By 2016, the inlets of the Eastern Route water channels in Jiangsu were guarded at all times by a 9650 kilometres long sewage collection pipeline network and approximately a fifth of the province’s total sewage treatment capacity.

(photo: 缪宜江)

Added on top were a total of 426 pollution control programs across vast areas of nearby lakes and wetlands, which acted as a ‘shield’ against pollution that stretched more than 1000 kilometres along the route. Right before the Eastern Route started operating in 2012, the total amount of pollutant entry along the route was reduced by 85%.

The water quality in all 36 cross-sectional water sampling sites was finally up to standard.

(photo: VCG)

In contrast to those in the Eastern Route, the main trunk line of the Central Route was sealed off from the start. The neighbouring regions along the route were also reserved for water conservation, essentially eliminating any potential impact from external sources of pollution.

Some even called the Central Route a ‘clean water corridor’.

But is it really?

During the 1980s, the water quality of Danjiangkou Reservoir, the originating site of the Central Route, was at Grade I for about two thirds of the time. But since the beginning of the 21st century, Grade I water quality was recorded only a third of the time.

How to maintain water quality at the source became the next big question.

(photo: 徐欣)

The upstream basin of the Danjiangkou Reservoir passes through a total of 600 towns, 43 counties and 8 cities in Shaanxi, Hubei and Henan. It would be a lot of hassle to trace back to the source of potential pollution in all three provinces.

But there were no other better solutions.

So, all the most polluting industries with poor emission control around the upstream basin of Danjiangkou Reservoir, including mining and smelting, diosgenin production and automotive plating, were all shut down.

Up till 2014, the number of urban sewage treatment plant grew from 5 to 174, and that of waste disposal site from just 1 to 99. These were accompanied by intensive management of a soil erosion area of 17,000 square kilometres.

(photo: 徐欣)

Since coming into service, the temporal ratio of Grade I quality in cross-sectional water samples of the Central Route has increased from 30% to 80%.

The water source protection program that lasted for more than 8 years is gradually delivering.

Sitting in the middle of lovely mountains and waters, the Danjiangkou Reservoir is certainly an excellent water source the Central Route.

But this comes at a huge price.

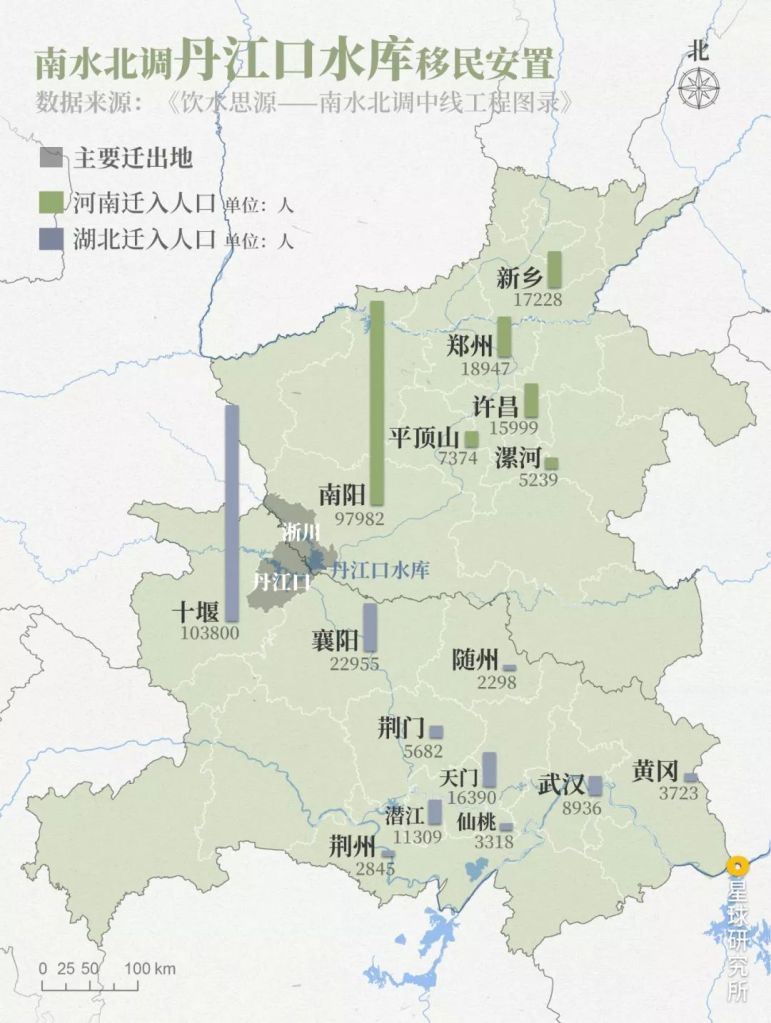

When the water level was elevated by 13 metres, the reservoir engulfed the neighbouring land of more than 300 square kilometres. This had forced a population of 340,000 from 441 villages and 40 towns to leave their homes behind.

(photo: VCG)

Moreover, approximately 90,000 citizens were awaiting resettlement from regions now occupied by the newly constructed water channels along the route.

The Central Route was in fact a bold and arduous resettlement project.

Colour: Main move-out area (主要迁出地, grey), immigration population in Henan (河南迁入人口, green) and Hubei (湖北迁入人口, blue)

Danjiangkou Reservoir (丹江口水库): Xichuan (淅川), Danjiangkou (丹江口)

Henan (河南): Xinxiang (新乡), Zhengzhou (郑州), Xuchang (许昌), Pingdingshan (平顶山), Luohe (漯河), Nanyang (南阳)

Hubei (湖北): Shiyan (十堰), Xiangyang (襄阳), Suizhou (随州), Jingmen (荆门), Tianmen (天门), Wuhan (武汉), Huanggang (黄冈), Qianjiang (潜江), Xiantao (仙桃), Jingzhou (荆州)

Data source: South-North Water Transfer Project Catalogue (饮水思源–南水北调中线工程图录)

(diagram: 王朝阳 & 陈睿婷, Institute for Planets)

In all the move-out areas to be submerged in water, a full-scale census was carried out. Every village and family, house and land, even a well and a tree, was carefully documented. Based on these records, the people moving out would be given a land acquisition compensation and a resettlement fee that is worth 16 times their three-year average economic output.

(photo: VCG)

The construction of immigration villages in the resettlement areas was equally intense at the time.

Considering the unique situation in each family, there were no less than 10 apartment unit types to be chosen by the immigrants. The new community is equipped with comprehensive infrastructure, including commute, power and water supply, household waste and sewage disposal and recycling, as well as schools.

For the majority of these immigrants, resettlement meant moving from mud-brick houses with a size of 20 square metres per person into masonry houses of 24-34 square metres per person.

(photo: 徐欣)

In addition, to make sure the immigrating farmers would have sufficient land for growing crops, high quality fields in the confined resettlement area were carefully identified and allocated to the immigrants.

The allocation has to be impartial, which took some serious efforts.

In the end, immigrants would either receive no less than 0.4 mu (1 mu is approximately 0.16 acre) of greenhouse field, no less than 1.05 mu of paddy fields and orchards, or at least 4 mu of dry land per person. Prior to resettlement, per person farming land for these citizens were only about 0.96 mu.

(photo: Promotion Centre of the Construction and Administration Bureau of South-to-North Water Diversion Middle Route Project)

With that settled, everything was finally ready.

On a long resettlement motorcade, more than 340,000 migrants bid farewell to their native land on which their ancestors had lived for generations.

(photo: VCG)

Together with their families, they would begin a new life far away from home.

(photo: VCG)

The time allowance for the whole resettlement project was just 2 years.

This was a record-breaking accomplishment in the history of migration associated with hydraulic engineering project worldwide.

To the migrating people, though, it was about giving up.

Not just the houses and farms, but also the home they know, and their way of living, which told generations of folk stories and fond memories.

For them to integrate into their new homes, it will require much more than the support and compensation from the government. They will need the acceptance from the local neighbours, as well as their own hard work and immense courage to rebuild everything.

A long journey ahead.

Newcomers in the village were welcomed by hundreds of outdoor banquets on 1 December 2018

(photo: VCG)

Villages and farms were not the only victims of the elevated water level of the Danjiangkou Reservoir.

What would also become submerged in water were 214 heritage conservation sites, including the Yuzhen Palace on Wudang Mountain built in the Ming Dynasty.

Back in 1967 when the Danjiangkou Reservoir was first built, the Jingle Palace in the ancient architectural complex on Wudang Mountain was unfortunately drowned forever due to technical limitations.

40 years later, engineers would not let this happen again to the Yuzhen Palace.

They decided to take a risky approach, which was to completely dismantle the main buildings and the palace walls of the Yuzhen Palace. They would subsequently raise the foundation, on which the palace would be reassembled.

All removed components were annotated and stored away, only to be restored as closely to the original state as possible after the foundation was raised to a suitable height. The three stone gates known as the Mountain Gate, East Palace Gate and West Palace Gate, on the other hand, were directly lifted up by 15 metres, which is approximately 5 stories tall.

Photo shows the lifting of the stone gates of Yuzhen Palace, please view with landscape mode

(photo: VCG)

Engineers first stabilised the building body of the Mountain Gate with steel frame and consolidated the pedestals with concrete. They then used several dozens of jacks to slowly lift up the stone gate weighing about several thousand tons.

It took almost six months for the three stone gates to reach their new height. Shortly after that, the Yuzhen Palace complex covering 24,000 square metres reappeared as it used to be on the new foundation.

Since the Eastern and Central Routes go past 710 heritage sites, immense effort from the South-North Water Transfer Project was directed to heritage protection.

There had been countless adjustments and rerouting throughout the planning and construction phases to protect the archeological sites along the route of water transfer. This was in coordination with continuous archeological investigation and excavation. Of all the findings, nine were listed in China’s Top 10 Archeological Discoveries of the Year.

On 14 November 2013, just 400 days before the Central Route started operating, a 2835 metres long dam across the Han River was completed. Located around 400 kilometres downstream of the Danjiangkou Reservoir, the dam is known as the Xinglong Water Conservancy Hub.

Accompanying it slightly further downstream is the water channel of the Yangtze River-to-Han River Water Diversion Project, which originates in the distant southwest and diverts approximately 3 billion cubic metres of water from the Yangtze River into the Han River every year.

It diverts water from the Yangtze River, through the Chang Lake (长湖), to the Han River downstream of the Xinglong Water Conservancy Hub (兴隆水利枢纽)

(diagram: 王朝阳 & 陈睿婷, Institute for Planets)

They are both part of the ecological compensation project of the Central Route, which aims to prevent excessive water diversion and the consequent drop in water level in the lower course of Han River that may impact local farmland irrigation and the river ecosystem.

By trapping water in the upstream and replenishing in the downstream, this intervention increases irrigation area in the former by more than 60%, and raises the multi-year average water level by 0.15-0.30 metres in the latter.

On the other hand, with the reconstruction and expansion of gating stations as well as partial redirection of navigation channels, the commuting distance between Jingzhou (middle Yangtze River basin) and Xiangyang (middle Han River basin) is reduced by 600 kilometres.

(photo: 傅鼎)

Pollution control, water source protection, resettlement, heritage protection and ecological compensation are but a few of the many “hidden” projects that made the South-North Water Transfer Project possible.

But they will likely remain unsung as most people continue to focus on the economic opportunities that come with the water from the south.

4. The next wonder 下一个奇迹

The Phase I of South-North Water Transfer Project has a 5599 kilometres long trunk line that contains 63 million cubic metres of concrete in volume. This is twice the volume used in the Three Gorges Dam, making it another hydraulic engineering wonder in China.

Operating at its full capacity, the project supplies water from the Yangtze River to almost 300 counties and cities.

It accounts for more than 70% of the water supply to Beijing, and above 75% to cities including Shijiazhuang, Handan, Baoding and Hengshui. In addition, it has become the sole water supplier for the urban areas in Zhengzhou and all 14 districts in Tianjin.

(photo: VCG)

Tens of thousands of farmlands can now enjoy an extra 2 billion cubic metres of irrigation volume. About 6 billion cubic metres of agricultural water previously seized for urban use, and purified water reclaimed from sewage treatment, can now also return to the farms.

Replenished by water from the south, the volume of Miyun Reservoir increased steadily over time and has now exceeded 2.6 billion cubic metres.

This is 3 times the volume back in 2003.

Image source. USGS

(diagram: 王朝阳 & 陈睿婷, Institute for Planets)

The alleviation of water shortage has not only reduced groundwater exploitation by 5 billion cubic metres per year, but also provided a surplus to compensate for previous overdraft.

As of 2018, the groundwater level in Beijing had risen by 2.63 metres since the southern water first entered the capital city.

Due to the reduced utilisation of groundwater in Beijing, the hardness of drinking water dropped by 70%. More than 5 million citizens in Northern China no longer need to drink brackish water or water with high fluoride content.

Groundwater level, measured by ground depth (埋深/m), started to rebound in 2016

Data source: Beijing Water Resource Bulletin (北京市水资源公报)

(diagram: 陈睿婷, Institute for Planets)

The success in ecological river restoration led to substantial mitigation of water pollution problems, which is most apparent in the flourishing downtown of Tianjin and the Baiyang Lake with blooming lotus.

(photo: VCG)

Since the completion of Eastern Route Phase I, the Beijing-Hangzhou Grand Canal has become the “golden waterway” that allows uninterrupted navigation between the Yangtze River and southern regions of the Yellow River.

With 13.5 million tons of additional cargo capacity, the Grand Canal is almost comparable to the Beijing-Shanghai Railway.

(photo: VCG)

The South-North Water Transfer Project is truly an engineering wonder.

It passed numerous assessments with meticulous planning and experimentation.

It overcame obstacles one after another during its construction and operation.

It kept its promises when faced with controversies.

It is a wonder created collectively by hundreds of thousands of migrating citizens, hundreds of thousands of engineers and construction workers, thousands of scientists and technicians, as well as those who dedicated their lives to this grand project.

(photo: VCG)

Today, the endless inflow of southern water brings with it not only a moment of respite for the dry lands in Northern China, but also precious opportunities.

The upcoming challenges will be to use the gift from the south sensibly and to its full potential. And these will have to be taken on by the direct beneficiaries of the project, i.e. the 120 million citizens from more than 260 counties and 40 medium and large cities in Northern China.

In doing so, perhaps they will create the next engineering wonder.

Production team

Editing: 张楠

Photos: 余宽, 刘白

Design: 陈睿婷, 郑伯容

Maps: 王朝阳

Review: 王朝阳, 云舞空城

Acknowledgements

Promotion Centre of the Construction and Administration Bureau of South-to-North Water Diversion Middle Route Project

王亦宁, Senior Engineer; Development Research Centre of the Ministry of Water Resources of PR China

References

- 北京市南水北调工程建设委员会办公室,北京市文物局. 《饮水思源——南水北调中线工程图录》[M]. 北京燕山出版社,2014

- 国务院南水北调工程建设委员会办公室. 《南水北调工程知识百问百答》[M]. 科学普及出版社,2015

- 《中国南水北调工程建设年鉴》编纂委员会. 《中国南水北调工程建设年鉴2017》[M]. 中国电力出版社,2017

- 文丹. 《南水北调中线工程》[M]. 长江出版社,2010

- 陈志康等. 《南水北调中线一期水源工程丹江口大坝加高设计》[C]. 大坝安全与新技术应用,2013

… The End …