Scientists at China’s Inner Mongolia University of Technology have conceived a lifecycle-based average consensus algorithm that they say can balance power in flywheel energy storage array systems and extend their overall lifespan. The impact on the environment is extremely low.

Read more: https://www.ess-news.com/…/extending-lifecycle-of…/

Extending lifecycle of flywheel energy storage via average consensus algorithm – Energy Storage

What is flywheel energy storage?

Flywheel energy storage, also known as kinetic energy storage, is a form of mechanical energy storage that is a suitable to achieve the smooth operation of machines and to provide high power and energy density.

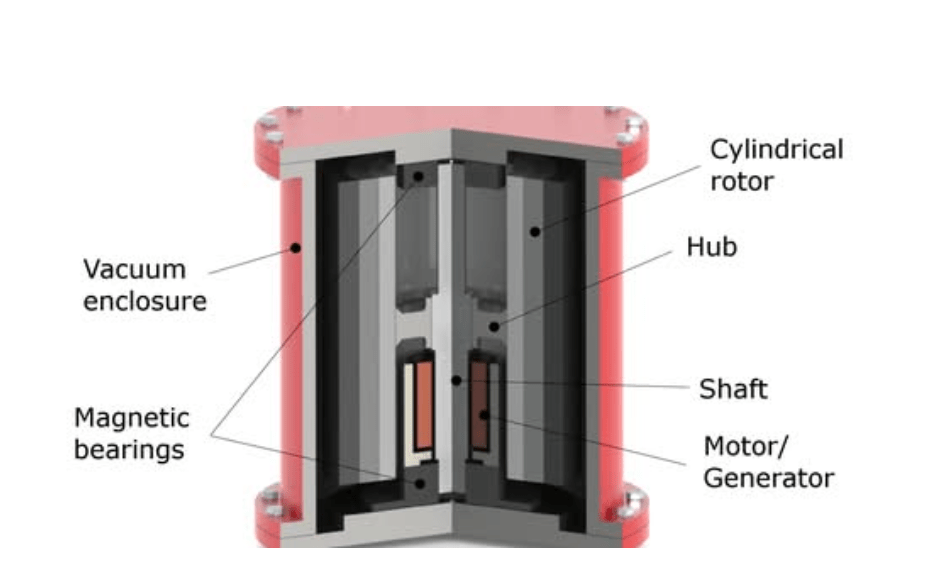

In flywheels, kinetic energy is transferred in and out of the flywheel with an electric machine acting as a motor or generator depending on the charge/discharge mode.

Permanent magnet machines are commonly used for flywheels due to their high efficiencies, high power densities, and low rotor losses [54]. Other electrical machines such as induction, bearing-less and variable-reluctance machines vary in terms of limitations in application speed, idling losses, vibration, noise and cost. Charging energy is input to the rotating mass of a flywheel and stored as kinetic energy. This stored energy can be released as electric energy on demand.

The rotating mass is supported by magnetic bearings which operate in a vacuum to eliminate frictional losses during long-term storage and safety issues [55]. The rotor bearing system can be mechanical or magnetic or a hybrid system of both to take advantage of the strengths of each type.

The magnetic bearing has no lubrication requirements as it has no frictional loss, but it has complicated control systems and some types require energy to operate. Superconducting magnetic bearings (SMBs) are suitable for high-speed applications, but require energy to operate a cryogenic cooling system.

Achieving high rotational velocity, with high power density, in flywheels is desirable since the energy stored is proportional to the square of the velocity but only linearly proportional to the mass. The key enabling technologies are in systems engineering and material science [9]. Steel, alloys (e.g., titanium or aluminum alloys) and more recently strong materials such as composites are used for the flywheel rotor and the housing that contains it.

Much research is focused on rotor materials and design and speeds of up to 10,000 rpms can now be achieved [54]. The use of composite materials enables high rotational speeds with greater power densities than chemical batteries. High power density is desirable in vehicles where a large peak power is needed when accelerating and a large power becomes available for storage in a short time when braking.

In addition to high energy and power density, high cycle life (many tens of thousands), long operational life, high round-trip efficiency, and low environmental impacts are also attributed to flywheel energy storage systems [56].

Compared to batteries and supercapacitors, lower power density, cost, noise, maintenance effort and safety concerns are some of the disadvantages of flywheel energy storage systems [126, 127]. To improve their power density, Toodeji [127] proposes a novel design for a combined system in which supercapacitors are located inside the flywheel rotating disk. This allows exchanging pulsed power as well as storing large amounts of energy.

From: S. Koohi-Fayegh, M.A. Rosen, in Journal of Energy Storage, 2020.

https://www.sciencedirect.com/topics/engineering/flywheel-energy-storage